This CE Center article is no longer eligible for receiving credits.

Serving as the very first impression to both building entrants and passersby, the building facade not only plays a major architectural and aesthetic role, but it significantly factors into a facility’s energy performance and sustainability.

Essentially serving as a building’s wrapping—be it glass, aluminum, aluminum composite, structural steel, or wood—an extensive array of shapes, colors, styles, and textures combine to present the building’s entry.

Photo courtesy of W&W Glass, LLC

A high-span glass cube entrance and curtain wall system clads the IBI Group-designed RioCan Yonge Eglinton Centre Complex in Toronto.

“The facade is of paramount importance in terms of building performance and is an important architectural element, ranking alongside building site and form,” confirms Mikkel Kragh, Ph.D., MSc, CEng, chairman, Society of Facade Engineering, Copenhagen, in an Intelligent Glass Solutions article titled “Facade Engineering & Design Teams of the Future.”

Shielding the building from the elements—i.e., rain, snow, wind, UV rays, insects, birds, etc.—the facade also serves as the building’s main protective layer, further underlying its importance within the overall building design.

Photo courtesy of EXTECH/Exterior Technologies, Inc.

A wood-faced operable paneled kinetic facade delivers an old New England aesthetic, along with high-quality superior insulation and ventilation, for the Anmahian-Winton Architects-designed Community Rowing’s Harry Parker Boathouse and Ruth W. Somerville Sculling Pavilion in Brighton, Massachusetts.

“The facade of a building is its first line of defense,” states Howard Zimmerman, owner and principal, Howard Zimmerman Architects, New York, in a Cooperator New York article, “Facades 101: The Partnership of Form and Function.”

“It is a raincoat for the building,” he continues. “It keeps the elements out and insulates, while at the same time serving a decorative purpose.”

Furthermore, Kragh points out that the facade can make up between 15 and 25 percent of total construction costs, in addition to accounting for a large percentage of a project’s technical and commercial risks.

That said, it’s essential to dedicate sufficient time to the design, development, fabrication, and installation of the facade system and all of its components.

For example, close coordination between the trades must occur in order to ensure a weathertight facade and high-performance thermal systems. Furthermore, the facade must successfully integrate with numerous building systems, including the structural design, daylighting systems, HVAC design, and the building’s overall energy efficiency, particularly in light of increasingly stringent energy codes.

“The facade is the filter between the climate outside and the conditioned space inside. It determines the appearance of the building, and its performance relies on appropriate specification, design, and delivery of a multitude of components and systems,” adds Kragh.

Embarking upon a new design, architects have a multitude of cladding options to choose from to meet these performance objectives while delivering an attractive aesthetic.

ACM in the Mix

Among these assorted choices, aluminum composite material (ACM) panels are a viable option, known for their sleek aesthetic. The once pricey material, formerly relegated to high-end products, is now affordable, thanks to advancements in product technology, manufacturing efficiencies, and installation techniques. In fact, initial construction costs are often lower than some other exterior materials due to a faster installation process.

Good-quality ACM products also incorporate a finish so that the cladding requires virtually no maintenance for as long as 30 years. Other benefits include rainscreen protection and the material’s light weight, supporting reduced structural steel requirements.

A partially recycled material, ACM’s are 100 percent recyclable. If manufactured domestically, they can be sourced to within 500 miles of the installation site, thereby contributing to LEED credits.

While many ACM facades are flat panels laid out in a symmetrical grid, the more trendy designs are taking advantage of the ability to fabricate the panels into 3-D shapes, thereby lending a high-tech, modern look. ACMs can also be bent, curved, and joined together in just about any geometric configuration and are offered in a large assortment of colors and finishes.

In terms of attaching the cladding, manufacturers offer various options, such as a dryseal gasket joint, wet-seal caulked joint, and a painted aluminum finishing cap that covers the panel joints.

For 3-D designs, some fabricators utilize an attachment system capable of thermally isolating the aluminum attachments and panel surface from the building wall, thereby limiting the amount of thermal transfer of energy into the building from the outside.

“Our goal was to create the easiest and least-expensive ACM solution to install, period. Based on the feedback from architects, owners, and installers on 3-D wall panel systems with thermal performance, we feel that we have succeeded,” says Goran Glumac, vice president, Acpexpress, North Bergen, New Jersey.

Because the thermal isolation and insulation capabilities of ACM systems are often a function of the attachment system, these performance capabilities may also be available with flat systems. Some systems can also be fitted with thermal-break pads and insulated channels to further limit the transfer of energy.

A strong example of ACM concave panel ability is exemplified at The Bank of America headquarters in San Antonio where the curved lobby walls mimic the look of wood. With a rectangular attachment profile, the panels easily align across a vertical or horizontal space. The panels also integrate seamlessly into the mixed-material wall and provide a unique aesthetic to the modern design.

Photo courtesy of Cladiators

Featuring aluminum composite concave panels, The Bank of America headquarters in San Antonio presents a wood appearance.

On another project, Pablo M. Ipucha, associate AIA, senior project manager, Gene Kaufman Architect PC, New York City, specified the panels for performance and functional benefits.

“Incorporating ACM panels into our building envelope has benefited us in drastically reducing the width of the exterior wall while meeting the R-value requirements. We were able to add 6 inches of usable real estate to the floor plans all around,” he says.

Faux Wood à la Aluminum

Combining the durability and maintenance of aluminum with the richness and beauty of wood, faux wood aluminum cladding is another viable facade option available to architects.

Exposed to the elements, prefinished aluminum for soffits and siding in particular effectively wards off rot, mold, and the challenges associated with cold weather. Because the color is baked into the material, owners can avoid the issues of flaking, peeling, and warping.

To produce an authentic wood appearance, some wood grain technologies utilize an advanced powder coating system and machinery to manufacture the material. The result is an attractive wood aesthetic without the maintenance hassle and cost associated with wood cladding products.

Showcasing the beauty of faux wood and the benefits of aluminum, John Clark, principal, John Clark Architect Inc., Burnaby, British Columbia, Canada, specified 10,000 square feet of 6-inch, V-groove light cherry aluminum siding and soffit for the John Paul II Pastoral Centre’s Campus of Care in Vancouver.

Photo courtesy of Mayne Coatings Corp.

V-groove light cherry aluminum siding and soffit at the John Paul II Pastoral Centre’s Campus of Care in Vancouver deliver a beautiful wood appearance without the maintenance hassle thanks to aluminum composite material.

While aluminum composite, cementitious plank, and steel cladding were all considered, a wood-grained aluminum siding material turned out to be the best option for its aesthetic compatibility to a wood finish and noncombustibility. Clark was also pleased with the cladding’s no shrinkage and no staining benefits, and the fact that the system he specified utilized a hidden fastening system.

Located in a residential area rich in trees and greenery, the facade’s wood appearance blends in well with the locale.

“The scale and color of the 6-inch plank material, relative to the volume of the wall areas and feature elements, informs and strengthens the relationship of the forested southwest edge of the property, its tall trees and adjacency to the residential neighborhood, and the neighboring health-care facilities,” Clark says.

In particular, the light cherry color was selected for its red tones, creating a nice contrast with the nearby Douglas fir and yew trees.

Sharing some lessons learned from the project, Clark advises building teams to preplan where the boards will be cut to avoid waste, knowing where the expansion channels and flashing details for windows and other openings will be placed, and extensive mockup training for the sub trades before installation.

The Beauty of Aluminum Trims

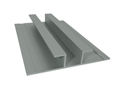

Another popular aluminum cladding choice is the application of extruded aluminum trims for assorted panel systems. Enhancing aesthetics and the creation of modern architectural lines, these trims are lightweight, durable, sustainable, noncombustible, easy to install, and available for both exterior and interior use.

Architects can choose from a wide variety of exterior detailing options, such as wide horizontal breaks, verticals that are accented or fade into a monolithic form, and corners that offer open reveals or closed sharp angles.

While galvanized trims frequently offer a lower first cost, aluminum delivers longer-term longevity and ultimately a better life-cycle cost, particularly when powder coated, anodized and/or primed, and ready-to-accept paint finishes are applied.

“Using extruded aluminum trim between panel joints becomes an architectural element and is a way of expressing the joints and defining their deliberate placement. It adds a level of architectural refinement,” says Russell A. Hruska, AIA, principal and co-founder, Intexure Architects, Houston. “In our climate, stucco often requires additional oversight to be correctly executed. Aluminum trim, when used with fiber cement panels or lapped siding, is more cost effective than stucco and provides long-term durability while achieving our design aesthetic.”

For example, Houston architect Val Glitsch, FAIA, selected extruded aluminum trim to create reveals in the panel and lap, inside and outside corner conditions, and between materials for the city’s New Hope Housing project.

Photo courtesy of TAMLYN

Extruded aluminum trim creates reveals in the panel and lap, inside and outside corner conditions, and between materials at the New Hope Housing project in Houston.

Glitsch chose not to go with wood trim, as it is a bulkier product and for water infiltration purposes can only be used for vertical joints. The panels themselves are a mix of fiber cement panel and lap, stucco, and brick.

Sharing some project details, Glitsch states, “We could have had a metal shop make up the trim pieces, but that’s not always a good way to get a quality, consistent, and cost-effective product. And the heavier-weight trim we used makes it easier to install the product properly.

Another recent example in the Lone Star State is Texan26, off-campus living for University of Texas students in Austin. For this project, in addition to the fiber cement panel and extruded aluminum used to create a reveal system, the building team added a drainable wrap to create a micro-rainscreen effect. The particular product chosen effectively maintains a 11/2-millimeter gap between the wrap’s primary surface and the cladding material thanks to an integrated filament. As a result, the wrap can remove 96 percent of the moisture that accumulates on the facade.

The omni-directional wrap also offered the Texan26 contractors an easier installation process. Together with a double-sided tape, as opposed to typical seam tapes, this enabled the installers to maintain a positive shingle installation throughout, which is best practice preached by the building science community.

As a side note, the codes are starting to catch up with accumulating research and building science expertise, stressing the importance of a building’s ability to effectively drain its walls in order to protect the integrity and performance of the building envelope. As a result, it is anticipated that housewraps will increasingly be judged by how effectively they provide positive drainage of water from the wall.

The Structural Steel Decking Option

Architectural metals, such as aluminum and aluminum composite, are a frequent choice for building facades because they are included in the Construction Specifications Institute’s Division 7, which addresses thermal and moisture protection.

However, an often over-looked option, tucked away in CSI’s Division 5 Metal Construction section, is exposed structural steel decking systems, which offer the distinct advantage of doubling as a structural system, thereby addressing form and function. By transferring load forces into the structure, this directly contributes to the building’s integrity, thereby reducing the overall project cost.

Available in curved, smooth, ribbed, or lineal plank patterned to create attractive exteriors, the exposed design also supports spacious interiors. With the open plenum design, lighting, electrical, plumbing, and fire suppression can be readily integrated, and by taking advantage of coated and textured options, such as bold fluted and smooth lineal textures, longevity is enhanced. Acoustical treatments are also available to help absorb sound energy.

With all these benefits, architectural decking is increasingly used as ceiling and cladding solutions for stadium exteriors and roofs, natatorium ceilings, open-air walkways, screens, and canopies.

Putting this into practice, the architect Populous chose an exposed architectural steel deck for the Minnesota Twins’ Target Field’s exterior cladding system, breaking away from the application of high-end, high-cost architectural metal exteriors.

Photo courtesy of New Millennium Building Systems

Looking for an alternative to high-cost architectural metal exteriors, Populous specified exposed architectural steel deck for the new exterior cladding system at the Minnesota Twins’ Target Field, capturing cost savings and adding to the canopy’s structural integrity.

“Populous was looking for an alternative, lower-cost cladding system,” recalls Marty Williams, design development manager, New Millennium Building Systems. “They were surprised to learn that an exposed structural steel deck system would address their aesthetic needs and more.”

Ultimately, a 2-inch-deep, dovetail-shaped steel decking system not only optimized design and cost, but the system added to the structural integrity of the canopy.

The installation crew closely coordinated with the fabricator to provide detailed drawings and scaled structural models showing how the customized trim sections would integrate with the dovetail steel decking system. Installation was then efficiently directed with the steel decking arriving in staged deliveries. Deck sections spanning up to 15 feet were protected by a strippable film, enabling the installers to position, strip, and install each section without mars or scratches.

The trim pieces, brake formed by the installer, utilized the same steel coil as the decking. Furthermore, PVDF factory-finished, galvanized steel coil provided a 20-year protection rating to the finished system.

Ultimately, selecting a structural steel cladding system delivered key form and function benefits, an outcome derived from getting off of the Division 7 beaten path.

The Warmth of Natural Wood

While the offerings of cladding materials abound, the beauty and warmth of natural wood evokes a special feeling, making it a desirable facade option.

Of course, the typical maintenance requirements associated with real wood is often a stumbling block for design teams. Fortunately, these concerns are greatly minimized with the availability of high-pressure laminate (HPL) panels finished with natural wood, delivering the aesthetic of real wood without the hassle of maintenance. While other wood materials require a high level of regular maintenance (i.e., varnishing, sanding, cleaning, etc.), these rainscreen HPL panels now afford architects a high degree of imaginative design and offer clients a maintenance-free facade dressed in a genuine wood aesthetic.

More so, these materials are designed as a ventilated facade, contributing to the building’s performance, energy efficiencies, and sustainability. These panels are prefinished, ready to install with conventional woodworking tools, and meet code fire requirements for any building height and construction type. These systems are primarily specified for facades but are often used as soffits or as a louver system and screen walls. And because the panels can be cut to any size and curved and supplied with the wood veneer on both faces of the panel, this affords architects boundless design freedom.

Looking to showcase the allure of wood, architect Jean-Marc Bonfils was actively looking for a wood cladding product to symbolically serve as the door to the city of Beirut for his East Village condo project (not pictured). Looking to retake the language of the traditional 1920s wooden houses surrounding the neighborhood, Bonfils selected HPL wood-faced panels to clad the facade, which was also decorated by vertical gardens.

“Suddenly, we found ourselves with the possibility to have a very vivid building with a very natural material and use it in a very contemporary way,” says Bonfils, Jean-Marc Bonfils & Associates, Lebanon. “That vivid feature of wood is absolutely extraordinary.”

Incorporating wooden brise-soleil panels into the design, the East Village facade texture changes with the sun and rain, creating a dynamic look.

Offering some perspective on the trend, Lourdes Hidalgo-Gato, sales manager, Prodema North America, relates that building envelope design has seen a significant transformation, especially in the United States and Canada, over the past decade. “Building science has taken a prominent role in response to higher standards for R-value requirements, resulting in a focus and growth of high-performance facade systems.”

Photo courtesy of Prodema

At the Owensboro Medical Health System in Owensboro, Kentucky, a natural wood rainscreen panel was designed to help support the image of a healthy, sustainable hospital.

Anchoring it Down

One important aspect of installing the various cladding materials available to the architect is the application of an effective anchoring system. While there are many choices in the market, not all offer a fully concealed system, which can be key to supporting the project’s aesthetics.

It’s also import to select a system that supports the positioning of undercut anchor on the back of the panel without constraints. Of course, these anchors must also pass required testing for facade panel attachment, ultimately supporting a high load capacity without stressing the facade panel by lateral bracing. Fortunately, some concealed anchoring systems are capable of delivering a safety factor that is much higher than traditional mortar, dowels, or visible clips.

Finding a system that can support thin facades—even as thin as 6 millimeters—is an added bonus in terms of supporting a higher level of design creativity. This capability was key for Daniel Libeskind’s Vanke Pavilion exhibition designed for the 2015 Milan Expo. The striking free-form metallic facade is a flowing organic shape, originating from the architect’s free-hand sketch.

More than 4,200 tiles—a mixture of clays, quartzes, and feldspars—produce a dynamic, metallic glaze which creates an iridescent threedimensional effect. Depending on time of day, light incidence, and viewing angle, the facade shifts from deep red to shimmering gold.

But in order to attach this sculptural creation to the facade, invisible and secure anchors were essential. To achieve this, steel squares are anchored to the pavilion structure and welded to round calendered steel rods. Positioned on the back of the tiles, a special drill bit was used to produce the cylindrical hole and conical undercut in one step. This created the basis for the attachment of the undercut anchor—an anchor sleeve and a hex screw.

Upon inserting the screw, the anchor sleeve successfully settled into the undercut hole with a positive fit and free from stress. The various diameters of hole and undercut ensure a secure hold without loading the tile, thereby avoiding stress cracks.

Photo courtesy of TILE EZE

For Daniel Libeskind’s Vanke Pavilion exhibition designed for the 2015 Milan Expo, invisible structural anchors were used to attach more than 4,200 tiles made from clay, quartz and feldspar within the free-form metallic facade.

The All-Glass Facade

In addition to aluminum cladding and siding, steel decking, and specialized cladding attachment systems, glass curtain wall is an increasingly popular facade option, promoting daylighting, views, and a high-end aesthetic.

Whether it’s stick-built curtain wall, unitized facades, point-supported structural systems, storefront, or window wall, these transparent systems deliver a modern, inviting entry point to any building.

“Today’s glazing system designs are pushing the envelope in many ways. From energy and acoustical performance, blast resistance, and ever increasing glass panel sizes,” states Jeff Haber, managing partner, W&W Glass, Nanuet, New York. “It is critical to stay on top of the latest trends in technology and manufacturing and marry these to the engineering of the products themselves to ensure the highest level of performance and quality.”

It’s important to understand some key differences and applications between the different glass facade systems. Unitized curtain wall is made up of large factory-glazed glass units. The panels can be erected in a third of the time of a stick-built system, making it well suited for taller structures, where higher field labor costs exists, higher performance is needed, or where a large volume of repetitive prefabricated panel sizes are required.

Otherwise, the vast majority of low to mid-rise curtain walls utilize stick-built systems, which have long vertical pieces of aluminum spanning in front of floors with horizontal members spanning between vertical members to support and transfer the load of the glass back to structure. Unlike fabricated unitized curtain wall, most of the glazing and erection must be done on-site. However, the lead time is much shorter, less up front staging is required, and stick-built systems are a good fit for facades with lower required volumes and complicated conditions.

Meanwhile, window wall is an aluminum facade system that spans in between slabs, making it a good choice for small- to medium-height buildings with window sizes at 10 feet or less. Because window walls can be glazed from the floor slabs on the inside of the building, this is helpful for speed and ease of installation, as a head track and sill track is mounted to the slabs and the preassembled window wall panels are set into place. Any moisture in the system then drains out at the sill track at the base.

A less-expensive alternative to curtain wall and window wall, storefront systems are typically used for lighter-duty applications at the base of buildings. Glazed on the interior or exterior, these one-floor systems create a storefront at the retail level or entrance to a building.

Point-supported structural glass systems—a popular choice for highly transparent facades, entrances, atriums, and lobbies—are made from tempered glass panels (with or without holes) attached with bolted or clamped fittings to the structure. The face glass is usually hung off of the backup structure, which can be glass fins, steel members, or stainless steel cables.

The biggest difference between these systems and a typical structurally glazed aluminum curtain wall system is the way the point-supported systems are supported, which is anchorage at specific points. This requires that the glass support a greater temporary deflection and resistance to uneven loading at edges and stress at hole/clamp locations, but it also requires thicker glass than standard curtain wall.

When specifying point-supported systems, it’s important to consider a fully tested system and bringing in a sole-source provider with a turnkey package, as opposed to amalgamated parts and pieces of tempered glass with holes, spider fittings, etc. Some of these manufacturers can also tighten specific fabrication tolerances and minimize roller-wave distortion tolerance to produce flatter tempered glass sometimes required by higher-end projects.

When submitting design plans to these fabricators, it’s important to include details on the wind loading, live load deflection, backup structure, renderings, plans, elevations, sections, inelastic seismic drift (to determine what panel sizes may work based on movement during an earthquake), glass performance requirements (i.e., low-e, silk-screen, tint), and special requirements, such as hurricane-impact or blast resistance.

All of these inputs are important to determine what panel size, fitting size, and structural glass system configurations will work best for the project.

Because the curtain wall system is also tied into the building enclosure, serving as the first line of defense for air, moisture, and water infiltration, it’s important to utilize an experienced installer with expertise in erecting weathertight complex glass systems. Also, failing to hire an expert system fabricator can result in poor tempering of the heavy tempered glass used in structural glass applications, thereby showing visual defects, such as high roller-wave distortion and bow and warp in the glass.

A high-profile example of bringing in an experienced curtain wall system fabricator and installer team to engineer, manufacture, and assemble a complex project is the point-supported structural glass systems at Hudson Yards Tower C, 10 Hudson Yards in Manhattan’s west side.

Photos courtesy of W&W Glass, LLC

For the Kohn Pedersen Fox-designed 10 Hudson Yards in Manhattan, a point-supported structural glass system clads the 82-foot-tall cable wall lobby facade and a trapezoidal 207-foot-tall atrium cable wall for the 52-story high-rise.

The 52-story high-rise features an 82-foot-tall cable wall lobby facade and a trapezoidal 207-foot-tall atrium cable wall rising from the sixth floor to the 21st floor. Both walls were made from 10-foot-wide modules, which is quite large for a structural glass facade.

The lobby walls also incorporate two full-height structureless corners supported with a special thin stainless steel angled bar located directly behind each corner.

In order to limit solar heat gain, Kohn Pedersen Fox required low-e coatings in some areas. Working with the glass fabrication engineers, approximately 1-inch-thick low-iron laminated glass was specified.

Glass Entrance Systems

To better achieve the sought after all-glass profile, technological advances are focusing on enhancing sightlines while maintaining thermal performance. As a result, architecture today is pushing the boundaries of aesthetics and function.

One area where this is evident is with entryways, which are being designed as key facade focal points. For example, one of the latest entrance systems to hit the market supports door handle hardware on 1-inch insulating glass panels using innovative through-glass fittings. The result is an attractive “floating on air” appearance. The system also delivers an ultra-thin door stile width of 11/8 inches and an overall depth of 21/2 inches, significantly reducing the amount of visible hardware. This creates a striking aesthetic that showcases the beauty of glass.

Facades must not only provide aesthetic excitement, they must also deliver exceptional thermal performance due to increasingly stringent energy codes. Despite the entrance system’s thin frame, it features heavy-duty, thermally broken cladding that produces U-factors as low as 0.33. Its clamping system also accommodates all high-solar and energy-efficient glass options. In all, the progressive entrance system provides the unique combination of all-glass aesthetics with full-frame performance.

Highlighting the key role that a well-engineered entryway can play in a facade’s overall aesthetic is the new 9001 Cypress Waters office space in North Dallas. The 215,000-square-foot facility, owned by the Billingsley Company, was designed by GFF Architects and features a monumental, four-story trellis composed of layered aluminum tubing. Surrounding concrete panels are peeled back to reveal a delicate, thermally broken curtain wall behind the trellis, with unique T-shaped mullions and extended face caps. This creates clean, streamlined glass spans that maximize daylighting and views to an adjacent park.

Photo courtesy of Andrew Adkison, GFF

This GFF Architects-designed thermally broken curtain wall at the 9001 Cypress Waters office space in North Dallas, Texas, features unique T-shaped mullions and extended face caps.

To complete the grand entryway, GFF Architects selected a thermally broken, all-glass entrance system to boost thermal performance and enhance aesthetics. The system is engineered to meet air and water infiltration requirements as well.

GFF teamed up with contractor Adolfson & Peterson Construction and glazing contractor Denison Glass & Mirror Inc. to deliver the project.

“When we’re thinking about the design of a building that is speculative in nature, we’re looking at ways to amplify the impact of the primary elements composing the facade, and we consider how these elements can be articulated to meet the need for maximizing daylight and thermal efficiency,” states Maria A. Gomez, principal, GFF Architects, Dallas. “The doors at the main entrance solved the requirement for thermal performance and weather protection, while maintaining an upscale look that complements the clean facade.”

It’s to the architect’s advantage to select single-source manufacturers that are capable of delivering a full range of facade solutions, including windows, entrance systems, storefronts, and curtain walls. Some glazing manufacturers also offer metal systems (e.g., sunshades, railings, windscreens, point-supported structural fittings, metal cladding, perforated panels, etc.) in order to present a complete selection of facade options.

“A successful facade design relies on the architect’s coordination of different products to achieve the aesthetic and functional goals of their client. We’ve experienced success in our ability to simplify this process by supplying a wide variety of systems, options, and upgrades that accomplish the design intent while meeting performance requirements,” says George Heflin, sales director, CRL-U.S. Aluminum, Dallas.

Developments in Kinetic Facades

While glass curtain walls are a popular and effective solution, kinetic facades—defined as the ability to respond and adapt to the changing environmental conditions—take designs a step further by employing the facade as an active system, capable of reducing energy costs and HVAC requirements through enhanced daylighting and natural ventilation.

A marriage of form and function, these visually captivating facades reduce solar heat gain by shielding the building from direct sunlight, while still supporting natural ventilation within the structure. Kinetic facades are designed to proactively respond to changing conditions, thereby enabling the facade to function more efficiently.

“By actuating the facades and making them dynamic, they can now better adapt to the conditions and provide for improved comfort of the occupants by providing for more of the tasks at a higher level of performance,” explains Ryan Hansanuwat, faculty of the school of architecture, University of Southern California, in a paper titled “Kinetic Facades as Environmental Control Systems: Using Kinetic Facades to Increase Energy Efficiency and Building Performance in Office Buildings.” “The building can be constantly working toward a better environment for the user as opposed to simply protecting them from it.”

By partnering with a kinetic facade provider early in a project, building teams can more effectively meet structural requirements due to the inherent lightness and energy efficiency of kinetic wall systems. Additionally, a kinetic facade’s aesthetic qualities may help municipalities save money on Arts in Transit and percent-for-art compliance.

For example, kinetic facades elevate the quality of the ridership experience and disrupt the monotony of commuting by providing a dynamic, interesting sight.

Case in point, for the Logan Airport Parking Expansion project in Boston, Arrowstreet partnered with one of these providers to create a kinetic wall based around 6-inch square curved aluminum ‘flappers.’ Elevating the parking lot into an art installation, the flappers were assembled into 350 unitized panels to capture the dynamic patterns of the wind coming off the Atlantic Ocean. Because of the facade’s innovation and novelty, the fabricator provided several mockups and prototypes to ensure the flappers would meet the design intent.

Photo courtesy of EXTECH/Exterior Technologies, Inc.

Designing a kinetic facade for the Logan Airport Parking Expansion in Boston, Arrowstreet selected curved aluminum ‘flappers’ inside unitized panels to capture the dynamic patterns of the wind coming off the Atlantic Ocean.

“The kinetic facade provides a visual representation of an unseen and unpredictable natural phenomenon—the wind,” relates Jim Leslie, general manager, EXTECH/Exterior Technologies, Inc., Pittsburgh.

A total of 48,000 custom-made flappers, spanning eight stories high and 290 feet wide, deliver an array of cost and sustainability benefits: they allow air to flow through and ventilate the building, they permit visibility from the inside, and they deflect solar heat gain. Furthermore, the panels deliver an eye-catching aesthetic of the wind rippling across the flappers.

On another project designed by Anmahian Winton Architects for Community Rowing’s Harry Parker Boathouse and Ruth W. Somerville Sculling Pavilion in Brighton, Massachusetts, a wood-faced operable paneled facade evokes the look of New England’s traditional covered bridges and tobacco barns, while delivering superior insulation and ventilation for the largest rowing company in the country.

A CNC router was used to fabricate the panels in a variety of unique shapes, and aluminum extrusions support the wood panels in their various orientations. Meanwhile, panels of 16-foot-high operable windows are hinged at the top and bottom and open in the centers, driven by rack and pinion hardware. Designed to be easily operable and efficient, as many as 30 glass panels can be opened by a single drive mechanism.

In addition to the wood facade and operable wall panels, unique aluminum clips were fabricated to support a shingled glass wall on the adjoining sculling pavilion.

Some custom facade fabricators are capable of “delving so completely into the conceptual objectives of a project that it produces unexpected solutions that have the power to redefine a project for the better,” explains Alex Anmahian, principal, Anmahian-Winton Architects, Cambridge.

The Facade's Many Roles

From aluminum to steel to wood to glass, building facades play a very key role within buildings, serving a variety of essential functions.

“While the facade is an elegant component that helps to define the unique architectural aesthetics of the building, it also has the critical role related to energy performance and interior function of a building,” confirmed Dudley McFarquhar, Ph.D., PE, McFarquhar Group Inc., Mesquite, Texas, in a “Role of the Building Facade” white paper for the Building Enclosure Science & Technology (BEST3) Conference.

He concludes, “As technology continues to improve, different options for improvement become available for incorporation into building facades.”