Photo courtesy of CRL

The term shelter carries with it connotations of protection, safety, a cover, or a refuge. Innovative new facade materials and methods better facilitate these capabilities for buildings.

Facade Innovations

Seeing More Clearly:

Advances in Glazing

Glass products are certainly doing new things. Curtain walls, window walls, and glazed storefronts provide some of the most dramatic design details of a building. There are several trends driving innovation in these products.

First among these is more fabrication and assembly in controlled environments. Shop fabrication and unitization addresses field labor shortages, creates faster close-in, and better fit and finish because of controlled assembly. In the field, new products provide a high tolerance control on extrusions, creating easier assembly and tighter snap connections. This ensures a better fit and finish with significantly less rework or material adjustments at the jobsite.

Photo courtesy of YKK AP

Advances in glazing systems are allowing flexibility in both satisfying performance requirements and adapting to installation requirements. The window wall glazing system designed for the JW Marriott in Nashville, Tennessee, includes an innovative slab edge cover that yields the beauty and appearance of a curtain wall application.

As curved glass, large spans, and large lites of glass continue their design prominence, so do the demands placed on their performance. New glazing and framing technologies can achieve the project’s design and performance goals, including Impact Resistant and Blast Mitigating curtain wall systems; pre-glazed, thermally broken, impact-rated window wall systems; and blast mitigating glazed entrance systems. Curtain wall systems are available with inside, outside, or structurally glazed options. Stick built, unitized, and cassette (carrier frame) system options are available with many sightlines and mullion depths. allowing the design professional to control both performance and cost by selecting the ideal mullion depth for opening size and design pressure requirements. Optional face covers can expand design flexibility.

By offering superior insulation properties in a complete suite of thermally broken products, new glazed products can provide ecologically sustainable and economically sensible solutions for the entire building envelope. Upgrading a building’s framing system first can be the most cost-effective option for gaining LEED certification and exercising environmental intelligence. Advanced energy-efficient glazed facades are designed to provide the highest level of thermal performance, exceeding the industry’s most stringent green standards, including ASHRAE 189.1, before upgrading glass beyond standard alternatives. This enhanced framing creates a 2-1/2-inch sightline outside glazed curtain wall system utilizing thermal break technology with structural polyamide struts, in various widths, that accommodate standard 1-inch glazing units as well as advanced glazing options such as triple glazing and suspended film technology. To ensure long-term structural integrity, the dead load of the insulating glass rests on integrated structural supports, diverting this load away from the thermal barriers. Using an advanced thermally broken frame also provides warmer interior surfaces and increased resistance to condensation, and the ability to integrate with a building’s air-vapor barrier.

When considering innovations in glazing, a larger development is the adoption of triple-glazed curtain wall systems to further enhance thermal performance in facades and to provide exceptional U-factors. These triple-glazed systems often feature dual thermal barrier technology, employing two fill and debridge pockets and three thermal break points.

For a fenestration system to provide optimal energy efficiency, its components must be carefully selected so that, together, they can deliver the desired result. The framing systems must support the performance of the insulating glass, and vice versa. Insulating Glass Units (IGUs) with dual or triple glazing are key to a successful energy-efficient fenestration system. For the best results, they should be filled with argon or xenon gas and should incorporate low-emission (low-E) coatings. Low-E coatings, gas-filled insulating glass units, and the use of double or triple panes are all critical considerations. Also critical is working with the local authority having jurisdiction early in the design phase so that energy performance expectations and requirements are clear from the get-go.

Combining innovations in framing and glazing into entrances, storefronts, and glazed walls introduces engineering advancements that surpass industry standards in aesthetics and performance. Monumental glass doors spanning 10 feet tall and 4 feet wide can be specified with ultra-narrow 1-5/8-inch door stiles to convey a grand entrance and heavy-glass visuals. These designs achieve an AAMA CW (Commercial/Window) Performance Class rating and feature 1-inch insulating glass and a distinct full perimeter seal, offering year-round, all-weather performance. These systems also incorporate thermally broken components to deliver superior U-factors as low as 0.37. Dual polyurethane thermal break points in storefront systems act as a superior thermal barrier. This delivers U-factors as low as 0.37 using standard low-E glass, and 0.19 using specially configured insulating glass units.

With any facade material, water management is of crucial concern. New curtain wall designs feature pressure-relieved horizontals with patented water management systems that efficiently sweep infiltrated water to the exterior. This in-built water management system eliminates the need to install vinyl flashing, which reduces labor costs and saves time. Exterior and interior members are joined with an injection-molded thermoplastic connector, which provides total thermal isolation for superior thermal performance. With no exposed exterior vertical members, the system offers architects all-glass aesthetics via uninterrupted horizontal glass spans.

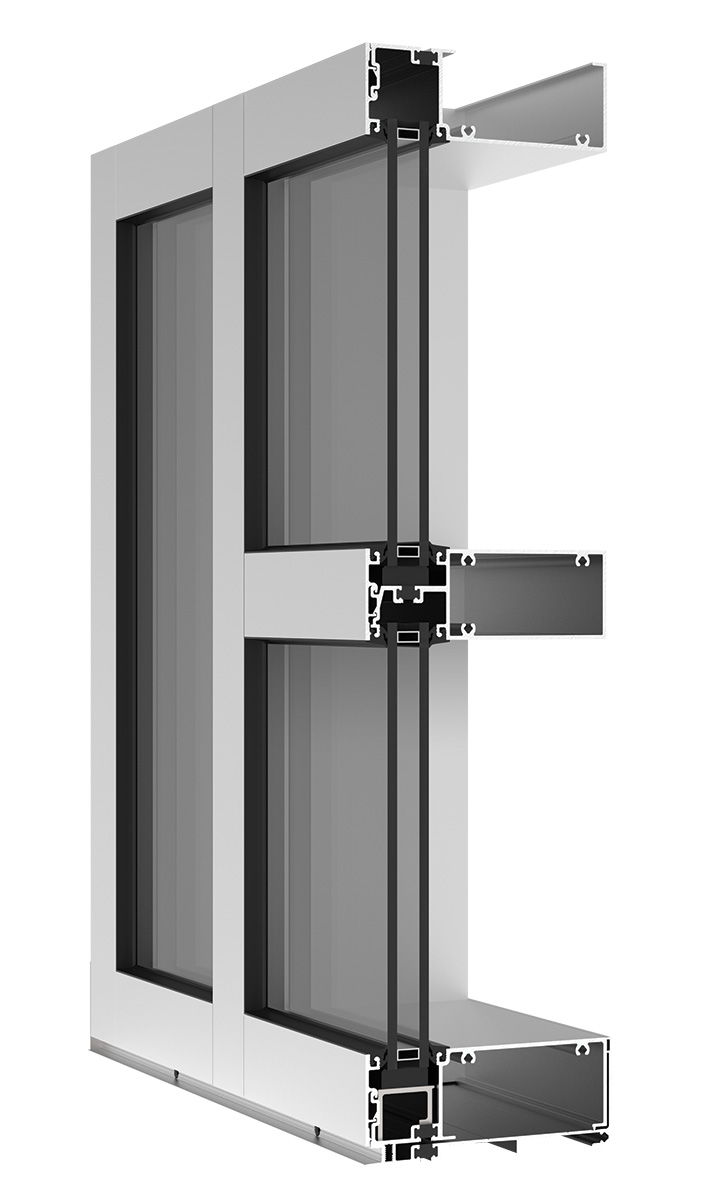

Photo © Ditz Fejer; courtesy of Rieder

Glass fiber reinforced concrete (GRC) combines the advantages of both materials. The quality, technical characteristics, and longevity of the natural product facilitate versatile and avant-garde applications. The authentic appearance creates a vivid facade. GRC cladding is designed as a mounted, ventilated facade and can be fixed in a visible or concealed manner.

Moving Materials Forward

The practice of providing a plane for moisture to drain down and off the exterior is centuries old. But the precise strategy and design of rainscreens have evolved dramatically over the years. Additionally, the materials used for the purpose of exterior moisture management have improved exponentially.

Glass fiber reinforced concrete (GRC) opens new possibilities for designs. Thanks to its low weight, flexibility in form, color, and surface finish, as well as its durability, GRC is a key new material for modern architecture. Sustainable facade elements made from glass fiber reinforced concrete (GRC) provide a unique combination of technical performance and environmental benefits.

Modern facades serve not only as architectural features but also as protective layers against wind, rain, and solar radiation, contributing decisively to the durability and performance of a building. GRC offers a long-lasting solution that meets the requirements of weather resistance, lightweight construction, and ease of installation, even in exposed locations. The manufacturing process used to produce GRC creates a material that is thinner, stronger, and more manageable for both design and installation. GRC elements are layered alternately, providing high tensile strength and durability. The thin, lightweight panels disprove misconceptions about using concrete in building facades—they are durable, flexible in design, and have significantly lower CO₂ emissions thanks to an optimized concrete matrix.

Significantly lighter than conventional concrete, GRC allows for efficient transport and handling of complex building envelopes, while prefabricated systems ensure fast and precise on-site installation. Its moisture-resistant structure and low susceptibility to soiling reduce cleaning effort and substantially extend the lifespan of facades. With a thickness of just 13 millimeters, low weight, and high span capacity, the elements are optimized for smooth implementation in the construction process. GRC is non-combustible, durable, and requires only minimal maintenance.

With a wide range of colors, textures, and formats, GRC facade elements provide extensive design flexibility. Architects can create bespoke, visually compelling building exteriors that harmonize with their surroundings while upholding environmental responsibility. A wide variety of formats, 3D shapes, colors, and surface finishes enable bespoke solutions. Custom-made special elements allow maximum design flexibility and adaptation.

GRC 3D elements offer high durability, low maintenance, and material-efficient production. Their dimensionally stable, thin-walled concrete structure minimizes material use while enabling a high-quality architectural appearance. Their combination of design freedom, technical intelligence, and functional value makes them an ideal solution.

Photo courtesy of Steel Dynamics, Inc. (SDI)

Digitally printed steel siding is the latest advance in printed steel, taking products a dynamic leap forward from older technologies.

Durability is also at the heart of advancements in steel facades. Woodgrain and stone-patterned printed steel have become increasingly popular in the past decade due to ease of maintenance and fire resistance, especially in commercial buildings. Digitally printed steel introduces a photorealistic appearance to this product category, making it suitable for use in projects where a hyper-realistic aesthetic is essential.

More traditional printed steel siding relies on Rotogravure printing. This process is extremely limiting in the quality and appearance of the end-product. Rotogravure, a technology developed in the 1860s for paper printing, uses an etched roll to apply paint or ink to a steel strip. There are limited colors per pattern, and the design repeats every 3-4 feet.

In contrast, high-resolution digital printing, developed recently, uses a large-format digital printer that outputs millions of color combinations in every pattern, with no repeats up to 32 feet. The resulting digitally printed steel product is comprised of galvanized coated steel sheet with a multi-layer paint system, printed ink layer, and solvent-free UV and scratch protective clearcoat, resulting in photorealistic prints sourced from high-resolution images of authentic natural materials, such as wood and stone.

Photo courtesy of Steel Dynamics, Inc. (SDI)

New digital printing technology allows for much longer repeats, stretching up to 32 feet, and prints millions of colors, resulting in photorealistic prints.

The large-format digital printer transfers the images onto sustainably made steel sheet at resolutions of up to 400 dpi. This detail allows for the inclusion of unique wood and stone features such as knots and cracks, which would be overly noticeable on a shorter repeat. The finished product can be rollformed, slit, or stamped into nearly any profile or shape, allowing it to serve as exterior siding, trim, soffits, fencing, interior walls, ceilings, and even furniture. Comprised of seven material layers—cold rolled steel base, galvanized coating, pretreatment, primer, topcoat, high-definition image, and solvent-free UV protective clear coat—each layer is melted, rolled, coated, or printed on one of the production lines. Production is controlled from start to finish, delivering a product that is both high-quality and sustainable.

Selecting Glazed Facade Systems for Capabilities and Standards

Glazed facade systems for commercial buildings cover a wide range of types, styles, installation methods, and attributes. These products carry various strengths and weaknesses, and their ultimate performance hinges on design pressure calculations, installation, and glazing processes. Structural requirements, thermal performance, assembly method, water management, and glazing method all weigh in to help the design professional determine the most appropriate facade choice.

Figure courtesy of YKK AP

Window wall assemblies offer flexibility; units can be glazed inside, outside, or structural silicone (SSG) glazed. These assemblies can also be pre-glazed through the shop or stick built on the jobsite. Customized thermal performance is readily available.

Photo courtesy of CRL

The term shelter carries with it connotations of protection, safety, a cover, or a refuge. Innovative new facade materials and methods better facilitate these capabilities for buildings.

Facade Innovations

Seeing More Clearly:

Advances in Glazing

Glass products are certainly doing new things. Curtain walls, window walls, and glazed storefronts provide some of the most dramatic design details of a building. There are several trends driving innovation in these products.

First among these is more fabrication and assembly in controlled environments. Shop fabrication and unitization addresses field labor shortages, creates faster close-in, and better fit and finish because of controlled assembly. In the field, new products provide a high tolerance control on extrusions, creating easier assembly and tighter snap connections. This ensures a better fit and finish with significantly less rework or material adjustments at the jobsite.

Photo courtesy of YKK AP

Advances in glazing systems are allowing flexibility in both satisfying performance requirements and adapting to installation requirements. The window wall glazing system designed for the JW Marriott in Nashville, Tennessee, includes an innovative slab edge cover that yields the beauty and appearance of a curtain wall application.

As curved glass, large spans, and large lites of glass continue their design prominence, so do the demands placed on their performance. New glazing and framing technologies can achieve the project’s design and performance goals, including Impact Resistant and Blast Mitigating curtain wall systems; pre-glazed, thermally broken, impact-rated window wall systems; and blast mitigating glazed entrance systems. Curtain wall systems are available with inside, outside, or structurally glazed options. Stick built, unitized, and cassette (carrier frame) system options are available with many sightlines and mullion depths. allowing the design professional to control both performance and cost by selecting the ideal mullion depth for opening size and design pressure requirements. Optional face covers can expand design flexibility.

By offering superior insulation properties in a complete suite of thermally broken products, new glazed products can provide ecologically sustainable and economically sensible solutions for the entire building envelope. Upgrading a building’s framing system first can be the most cost-effective option for gaining LEED certification and exercising environmental intelligence. Advanced energy-efficient glazed facades are designed to provide the highest level of thermal performance, exceeding the industry’s most stringent green standards, including ASHRAE 189.1, before upgrading glass beyond standard alternatives. This enhanced framing creates a 2-1/2-inch sightline outside glazed curtain wall system utilizing thermal break technology with structural polyamide struts, in various widths, that accommodate standard 1-inch glazing units as well as advanced glazing options such as triple glazing and suspended film technology. To ensure long-term structural integrity, the dead load of the insulating glass rests on integrated structural supports, diverting this load away from the thermal barriers. Using an advanced thermally broken frame also provides warmer interior surfaces and increased resistance to condensation, and the ability to integrate with a building’s air-vapor barrier.

When considering innovations in glazing, a larger development is the adoption of triple-glazed curtain wall systems to further enhance thermal performance in facades and to provide exceptional U-factors. These triple-glazed systems often feature dual thermal barrier technology, employing two fill and debridge pockets and three thermal break points.

For a fenestration system to provide optimal energy efficiency, its components must be carefully selected so that, together, they can deliver the desired result. The framing systems must support the performance of the insulating glass, and vice versa. Insulating Glass Units (IGUs) with dual or triple glazing are key to a successful energy-efficient fenestration system. For the best results, they should be filled with argon or xenon gas and should incorporate low-emission (low-E) coatings. Low-E coatings, gas-filled insulating glass units, and the use of double or triple panes are all critical considerations. Also critical is working with the local authority having jurisdiction early in the design phase so that energy performance expectations and requirements are clear from the get-go.

Combining innovations in framing and glazing into entrances, storefronts, and glazed walls introduces engineering advancements that surpass industry standards in aesthetics and performance. Monumental glass doors spanning 10 feet tall and 4 feet wide can be specified with ultra-narrow 1-5/8-inch door stiles to convey a grand entrance and heavy-glass visuals. These designs achieve an AAMA CW (Commercial/Window) Performance Class rating and feature 1-inch insulating glass and a distinct full perimeter seal, offering year-round, all-weather performance. These systems also incorporate thermally broken components to deliver superior U-factors as low as 0.37. Dual polyurethane thermal break points in storefront systems act as a superior thermal barrier. This delivers U-factors as low as 0.37 using standard low-E glass, and 0.19 using specially configured insulating glass units.

With any facade material, water management is of crucial concern. New curtain wall designs feature pressure-relieved horizontals with patented water management systems that efficiently sweep infiltrated water to the exterior. This in-built water management system eliminates the need to install vinyl flashing, which reduces labor costs and saves time. Exterior and interior members are joined with an injection-molded thermoplastic connector, which provides total thermal isolation for superior thermal performance. With no exposed exterior vertical members, the system offers architects all-glass aesthetics via uninterrupted horizontal glass spans.

Photo © Ditz Fejer; courtesy of Rieder

Glass fiber reinforced concrete (GRC) combines the advantages of both materials. The quality, technical characteristics, and longevity of the natural product facilitate versatile and avant-garde applications. The authentic appearance creates a vivid facade. GRC cladding is designed as a mounted, ventilated facade and can be fixed in a visible or concealed manner.

Moving Materials Forward

The practice of providing a plane for moisture to drain down and off the exterior is centuries old. But the precise strategy and design of rainscreens have evolved dramatically over the years. Additionally, the materials used for the purpose of exterior moisture management have improved exponentially.

Glass fiber reinforced concrete (GRC) opens new possibilities for designs. Thanks to its low weight, flexibility in form, color, and surface finish, as well as its durability, GRC is a key new material for modern architecture. Sustainable facade elements made from glass fiber reinforced concrete (GRC) provide a unique combination of technical performance and environmental benefits.

Modern facades serve not only as architectural features but also as protective layers against wind, rain, and solar radiation, contributing decisively to the durability and performance of a building. GRC offers a long-lasting solution that meets the requirements of weather resistance, lightweight construction, and ease of installation, even in exposed locations. The manufacturing process used to produce GRC creates a material that is thinner, stronger, and more manageable for both design and installation. GRC elements are layered alternately, providing high tensile strength and durability. The thin, lightweight panels disprove misconceptions about using concrete in building facades—they are durable, flexible in design, and have significantly lower CO₂ emissions thanks to an optimized concrete matrix.

Significantly lighter than conventional concrete, GRC allows for efficient transport and handling of complex building envelopes, while prefabricated systems ensure fast and precise on-site installation. Its moisture-resistant structure and low susceptibility to soiling reduce cleaning effort and substantially extend the lifespan of facades. With a thickness of just 13 millimeters, low weight, and high span capacity, the elements are optimized for smooth implementation in the construction process. GRC is non-combustible, durable, and requires only minimal maintenance.

With a wide range of colors, textures, and formats, GRC facade elements provide extensive design flexibility. Architects can create bespoke, visually compelling building exteriors that harmonize with their surroundings while upholding environmental responsibility. A wide variety of formats, 3D shapes, colors, and surface finishes enable bespoke solutions. Custom-made special elements allow maximum design flexibility and adaptation.

GRC 3D elements offer high durability, low maintenance, and material-efficient production. Their dimensionally stable, thin-walled concrete structure minimizes material use while enabling a high-quality architectural appearance. Their combination of design freedom, technical intelligence, and functional value makes them an ideal solution.

Photo courtesy of Steel Dynamics, Inc. (SDI)

Digitally printed steel siding is the latest advance in printed steel, taking products a dynamic leap forward from older technologies.

Durability is also at the heart of advancements in steel facades. Woodgrain and stone-patterned printed steel have become increasingly popular in the past decade due to ease of maintenance and fire resistance, especially in commercial buildings. Digitally printed steel introduces a photorealistic appearance to this product category, making it suitable for use in projects where a hyper-realistic aesthetic is essential.

More traditional printed steel siding relies on Rotogravure printing. This process is extremely limiting in the quality and appearance of the end-product. Rotogravure, a technology developed in the 1860s for paper printing, uses an etched roll to apply paint or ink to a steel strip. There are limited colors per pattern, and the design repeats every 3-4 feet.

In contrast, high-resolution digital printing, developed recently, uses a large-format digital printer that outputs millions of color combinations in every pattern, with no repeats up to 32 feet. The resulting digitally printed steel product is comprised of galvanized coated steel sheet with a multi-layer paint system, printed ink layer, and solvent-free UV and scratch protective clearcoat, resulting in photorealistic prints sourced from high-resolution images of authentic natural materials, such as wood and stone.

Photo courtesy of Steel Dynamics, Inc. (SDI)

New digital printing technology allows for much longer repeats, stretching up to 32 feet, and prints millions of colors, resulting in photorealistic prints.

The large-format digital printer transfers the images onto sustainably made steel sheet at resolutions of up to 400 dpi. This detail allows for the inclusion of unique wood and stone features such as knots and cracks, which would be overly noticeable on a shorter repeat. The finished product can be rollformed, slit, or stamped into nearly any profile or shape, allowing it to serve as exterior siding, trim, soffits, fencing, interior walls, ceilings, and even furniture. Comprised of seven material layers—cold rolled steel base, galvanized coating, pretreatment, primer, topcoat, high-definition image, and solvent-free UV protective clear coat—each layer is melted, rolled, coated, or printed on one of the production lines. Production is controlled from start to finish, delivering a product that is both high-quality and sustainable.

Selecting Glazed Facade Systems for Capabilities and Standards

Glazed facade systems for commercial buildings cover a wide range of types, styles, installation methods, and attributes. These products carry various strengths and weaknesses, and their ultimate performance hinges on design pressure calculations, installation, and glazing processes. Structural requirements, thermal performance, assembly method, water management, and glazing method all weigh in to help the design professional determine the most appropriate facade choice.

Figure courtesy of YKK AP

Window wall assemblies offer flexibility; units can be glazed inside, outside, or structural silicone (SSG) glazed. These assemblies can also be pre-glazed through the shop or stick built on the jobsite. Customized thermal performance is readily available.

Types

Storefront and glazed entrances, window walls, and curtain wall systems are the most common glazed facades; each has specific applications and installation methods.

A storefront glazing system is a fixed glazing system that is typically installed on the ground floor of commercial buildings. These are designed to offer large, clear views, which enhance visibility and bring natural light into the building. Storefronts are non-load-bearing, relying instead on the building’s structure for support. Reducing load allows for the use of aluminum frames, providing a modern appearance with narrow lines. Frames are anchored between the floor slabs with glass panels installed within these frames.

Storefront glazing creates a basic, economical glazing system with quick assembly. It can meet minimum water and structural performance requirements; however, performance regarding thermal insulation and acoustic control is lower when compared to more advanced systems like curtain walls.

Glazed entrance systems offer an abundance of design options. Panel doors are mechanically joined and welded to ensure that they withstand the most demanding conditions. Engineering advancements allow for monumental glass doors spanning 10 feet tall and 4 feet wide, specified with ultra-narrow 1-5/8-inch door stiles to convey a grand entrance and heavy-glass visuals. Thanks to framing and glazing technological improvements, glazed entrances can earn an AAMA CW Performance Class rating. Insulating glass and a distinct full perimeter seal provide year-round, all-weather performance. Incorporating thermally broken components delivers superior thermal performance.

Window wall systems provide units of pre-glazed assemblies installed between floor slabs. Window walls are often specified for mid-rise to high-rise residential and commercial buildings. They offer a high degree of flexibility in design and can be adapted to various building configurations. Commonly used in ribbon window configurations or punched openings, window wall framing systems span from slab to slab and can be installed from the building’s interior to improve logistics and reduce installation costs. Window wall systems can also employ floor slab edge covers that enable the system to mimic the look of a curtain wall system at a significantly reduced cost.

Window walls, like storefront systems, allow for ample natural light, improving the indoor environment and reducing the need for artificial lighting.

Curtain wall systems clad a building envelope with glass and aluminum to protect the interior from the elements and create a safe and comfortable work environment for the building occupants. Curtain walls are designed to carry only their own weight. The curtain wall transfers wind loads to the main building structure, also known as the main wind force resisting system (MWFRS), at connection points in the floors or columns of the building. A curtain wall is designed to resist air and water infiltration, as well as sway created by wind and seismic forces, and its own weight.

Curtain walls may span from floor to floor, be used in punched opening applications, or span multiple floors. When designing curtain walls, it is critical to take into consideration design requirements such as thermal expansion and contraction; building sway and movement; water diversion; and thermal efficiency for cost-effective heating, cooling, and lighting in the building.

Selecting a window wall offers many advantages in today’s market, in which quick installation and cost advantage are critical. While glazed commercial facades are often designed as curtain walls, more recently, the window wall has emerged as an effective alternative for mixed-use buildings like offices and hotels.

Curtain wall systems are designed to sit in front of the building and anchor to each floor line. Window wall systems rest inside the building and span floor-to-floor. This creates a cost advantage over curtain wall systems, as structural requirements can be met with less material and reinforcement.

Additionally, due to their design, window walls do not transmit sound waves from floor to floor, creating better sound attenuation. This provides specifiers with more control over acoustical performance.

A key attribute of window wall systems is the ability to install and glaze from inside the building. This attribute is enhanced by the recent trend of pre-glazing, which further shortens installation time and requires less labor. Innovative slab edge covers enable window wall systems to provide a sleek, modern aesthetic and maximum design versatility. Paired with slab edge covers, window wall can mirror the look of curtain wall from a building’s exterior, while providing high thermal and acoustical performance.

Photo © Geoff Captain; courtesy of CRL

For a fenestration system to provide optimal energy efficiency and performance, its components must be carefully selected so that, together, they can deliver the desired result. This includes assessing framing systems and insulating glass capabilities.

Requirements and Considerations

When properly designed, specified, and installed, glazed facades can provide superior performance in terms of air and water infiltration, thermal insulation, and structural integrity. The use of advanced glazing technologies and materials can enhance the energy efficiency of glazed systems, making them suitable for high-performance buildings.

With any project that involves glazing or fenestration – whether it’s new construction or a retrofit application—architects must be aware of local codes that specify energy performance requirements and understand the National Fenestration Rating Council’s (NFRC) role in complying with these codes. NFRC labels provide an excellent guide to performance, whether the product is a window, door, or skylight. The labels detail several performance factors, including the product’s U-factor and Solar Heat Gain Coefficient. The U-factor measures heat transfer through a fenestration system. The lower the number, the better the product is at mitigating heat transfer. The U-factor ranges from 0.2 to 1.2. The Solar Heat Gain Coefficient (SHGC) measures how much solar heat a product allows in. Low numbers offer better resistance to solar heat, while high numbers allow more solar heat in. The SHGC ranges from 0 to 1.

The effort to improve the energy efficiency of buildings is primarily driven by energy codes and green standards. These include requirements from ICC codes and ASHRAE standards, as well as frame and glazing performance for the commercial market, such as AAMA 507 and NFRC Component Modeling Approach (CMA).

Partnering with local authorities in the early stages of the design process is key to success. In retrofit applications, architects should know that, although performance requirements for existing fenestration components can sometimes be grandfathered in, any new systems must comply with the energy codes of local jurisdictions. Additionally, unique considerations like blast rating, hurricane, and accessibility mandates need to be considered upfront in design.

Acoustic performance is also an increasingly relevant consideration in the construction market due to urbanization and connections between noise exposure and human health. Environmental noise pollution negatively impacts millions of people and leads to problems like “stress-related illnesses, high blood pressure, speech interference, hearing loss, sleep disruption, and lost productivity.”1 In order to obtain the desired level of acoustic performance, it is important to consider the type of glass and fenestration used on a building.

What’s Next

In today’s fast-paced construction environment, where labor continues to be challenging, pre-glazed options enable panels to be fabricated, assembled, and glazed in the factory rather than on site. This also permits the installation of the system from the inside of the building, a critical specification in spaces where construction sites are tight and space is limited. A pre-glazed system also speeds up the installation process and improves the safety of the installation team. Additionally, pre-glazed units shorten the construction cycle by allowing drying-in by floor.

Photo courtesy of YKK AP

The 110 East project in Charlotte, N.C., uses custom vertical glass fins extending in staggered lengths, creating a striking three-dimensional texture via window walls. The glass’s reflective and transparent qualities respond to changing daylight, giving the building a constantly evolving character.

Framing manufacturers continue to offer more advanced framing with extra thermal performance to meet and exceed codes and to save energy, without the need for advanced glazing. Older aluminum framing systems on the building envelope conduct heat very well; systems with more than one thermal break are the most effective at maintaining high thermal performance. The more thermal breaks between the exterior and interior of a building, the better the fenestration system is at mitigating heat transfer.

Codes such as ASHRAE 90.1-2022 and California Title 24 are setting the standard for building energy performance. California Title 24 standards provide a look into future requirements for glazed systems, particularly for coastal states that already have stringent energy codes.

Photo courtesy of Steel Dynamics, Inc. (SDI)

Woodgrain and stone-patterned printed steel have become increasingly popular in the past decade due to ease of maintenance and fire resistance, especially in commercial buildings.

Exploring Opportunities with GRC and Steel

More than a design element, modern facades act as architectural features and as protective layers against wind, rain, and solar radiation, all while contributing decisively to the durability and performance of a building. This means that the materials and construction of a facade must balance both design and function. The outer skin combines aesthetic ambition with functional purpose—protection against external influences, longevity with minimal maintenance, and an enduring aesthetic that lasts for decades.

Strong, Tough, and Reclaimable—Steel

Flat rolled steel siding is, in general, a cost-effective and extraordinarily durable solution for any facade. Steel facades first emerged on commercial buildings of the late 1800s and early 1900s, reflecting the widespread availability of mass-produced building parts, which ranged from individual components to entire building facades.2 3 Mesker Brothers Iron Works of St. Louis, Missouri, and George L. Mesker Company of Evansville, Indiana, specialized in early ornamental sheet-metal facades and cast-iron storefront components. Made of galvanized steel and cast iron, these durable facades often survive, despite occasional neglect and lack of maintenance.4

Today’s steel facades remain extremely durable and strong. Properly treated, steel can endure extreme weather conditions and is highly resistant to corrosion. It is also resistant to pests and fire. Steel cladding sheets offer exceptional durability and a long service life. With proper maintenance, these sheets will last for decades, significantly reducing the need for major repair work over time. Modern cold-rolled galvanized steel can also be coated with a thin layer of zinc to further improve its corrosion resistance. Cold rolled galvanized sheet steel is well-suited to surface-critical applications. In addition, galvannealed coating (steel that has been hot-dip galvanized and then subjected to a heat treatment, or annealing, to form a zinc-iron alloy coating) creates enhanced weldability. A variety of other surface treatments are available to further inhibit oxidation or to improve formability.

Particularly with advances in technology and digital printing, steel products offer exceptional versatility and can be designed and customized to suit any architectural style. Modern steel products provide design versatility in colors, textures, and finishes, allowing for both aesthetic and structural benefits. As demand for prints rises, the steel market anticipates the arrival of more exciting and unique print technologies and aesthetic solutions. With endless color and print combinations available, creative solutions to design challenges are boundless.

Steel facades featuring digital printing also satisfy required quality assurance certifications and general safety certifications.

These include ASTM-D523, ASTM-D5402, ASTM-D3359, ASTM-D4145, ASTM-D2794, ASTM-D3363, ASTM-D5796-24, ASTM-D1729/D4086, ASTM-D8331/ D8331M-20, which assess coating adhesion, deformation, thickness, quality, and resistance, as well as ASTM-E84 and ASTM-E2768 for fire resistance.

Steel facades are also a very modern material in terms of sustainability and environmental awareness. Most metals used in building facades, such as aluminum and steel, are highly recyclable and can be reused in other projects. Steel facades are a great way to reduce waste and promote environmentally conscious, circular building practices. Both in manufacture and during service life, steel is energy efficient, protecting a structure against temperature changes and enhancing comfort, which can also lower energy costs.

Photo © Ditz Fejer; courtesy of Rieder.

With a wide range of textures, colors, and formats—including 3D forms and large panel sizes—architects have far more creative freedom with glass fiber reinforced concrete.

Versatile, Durable, and Flexible—Concrete

Modern concrete challenges the view that concrete cannot be sustainable by delivering a high-performance, durable, and aesthetically versatile solution that unites form, function, and sustainability.

Extruded concrete is an ideal material for rainscreens for many reasons. The manufacturing process creates a material that is thinner, stronger, and more manageable for designing and installing rainscreens. This finished product, which can be rapidly produced, combines many of the desired attributes necessary for quality rainscreens and facades: it is noncombustible, durable, and available in a wide range of colors and finishes.

Glass fiber reinforced concrete (GRC) is produced with resource efficiency in mind. The half-inch-thick extruded concrete panel is reinforced with a glass fiber mesh and chopped glass. The combination of these components provides high tensile strength and a durable panel. The product is also extremely versatile for original designs, with options of different panel sizes and shapes. A wide variety of formats, dimensional shapes, colors, and surface finishes enable bespoke solutions. Custom-made special elements allow for maximum design flexibility and adaptation to urban contexts. Extruded forms offer a new way for designers to create and implement 3-D objects that go beyond a basic, flat panel. The extruded panels can take on different shapes, including “U”, “L”, or other special configurations, allowing for dynamic architectural expression on a building’s exterior.

Since GRC creates durability through precise layering, it can achieve strength via extremely thin panels, making the panels significantly lighter and easier to transport. The panels can also be installed quickly and precisely, thanks to prefabrication and planning during manufacture. Once installed, panels require very little, if any, maintenance. A GRC panel is durable, requires minimal maintenance, and contributes to extending building life cycles thanks to its robustness. GRC is also highly compatible with other materials. Extruded concrete forms are increasingly used in timber-hybrid construction, combining lightness and sustainability with robustness and fire resistance.

GRC also excels for projects seeking environmental and efficiency goals. Three-dimensional facade elements serve not only an aesthetic function but also can act as intelligent solar and privacy protection, reducing heating and cooling loads. Numerous projects featuring GRC facades have been certified according to international sustainability standards such as DGNB, LEED, and BREEAM. These distinctions demonstrate that architectural quality, technical performance, and ecological responsibility can be achieved together.

Photo © Ditz Fejer; courtesy of Rieder

A facade today is far more than just the outer shell of a building – it is an integral part of sustainable architecture, uniting aesthetics, functionality, and energy efficiency.

Sustainable Refuge

Facades and rainscreen systems are becoming a widely adopted part of building design. They offer a definitive water-mitigation plan, providing an essential part of a project. The shelter that they provide to a building also increases its durability and resilience, and thereby, its sustainability.

The construction sector has both the potential and the responsibility to drive change in sustainable building practices. The sustainability of a product begins with its materials. However, those materials undertake a journey to the finished product. The steps in that transformation can help or hinder sustainability goals.

Reducing energy consumption is another key to sustainability. A major innovation for steel manufacturing is the evolution of Electric Arc Furnaces (EAF) from Blast Furnace - Basic Oxygen Furnaces (BF - BOF). The latter uses iron ore and coke as the primary fuel, emitting substantial amounts of carbon dioxide. This antiquated approach is being replaced by EAFs that use recycled scrap metal as the primary input and electricity as their main source of energy. These facilities are smaller, have a lower environmental impact, and cut production time versus aging BOFs. U.S. EAF mills generate a fraction of the carbon emissions produced and energy intensity required by traditional BF-BOF steelmaking. EAFs produce substantially fewer emissions—69.83 percent less carbon emissions—and have an energy intensity that is 57.68 percent lower than BOFs.5 Innovative pathways are transforming the sources that power steel mills to meet these goals. The U.S. is among the world leaders in sustainable steel production. As of 2020, over 70 percent of U.S. steel production came from electric arc furnaces (EAFs), compared to only about 26 percent globally.6

U.S. EAF mills use recycled metal to produce new steel, facilitating lower emissions, energy, waste, and water usage. Flat roll, bar, and structural shapes are produced with significantly less energy. By connecting the casting and rolling processes in flat roll mills, EAF mills roll slabs into steel coils while the steel is still hot, requiring significantly less energy compared to traditional BF-BOF technology, which typically requires reheating slabs before rolling.

The production of sustainable steel starts with recycled content. When steel products reach the end of their life cycle, they are scrapped, recycled, and melted into new steel, completing a full circle. The combination of cutting-edge manufacturing and energy technologies and supply-chain efficiency enables steel products to achieve industry-low Scope 1 (direct) and Scope 2 (indirect) emissions as defined in the international Greenhouse Gas Protocol

GRC is also produced with resource efficiency in mind, is durable, requires minimal maintenance, and contributes to extending building life cycles, thanks to its robustness.

To reduce waste in the production of glass fiber reinforced concrete facade elements and minimize environmental impact, an innovative facade concept of using scrap concrete was developed using data analysis and generative design techniques. Digital software tracks leftover materials and creates project-specific design options for facades. The software uses already fabricated scrap pieces as the basis to generate a multiplicity of potential designs. The project transforms irregular, non-uniform stocks of concrete scrap into new forms, finding beauty and intricacy in neglected waste. By combining the logic of the quilt with a customized shape and pattern detection, the software, in effect, uses big data to tackle big waste, creating a search engine to find custom material solutions.

New techniques that marry digital technology and manufacturing have pioneered the development of CO₂-reduced concrete matrices, significantly lowering the carbon footprint of facade elements. This innovative approach aligns with the global shift toward greener construction practices and helps meet climate targets.

The gradual replacement of cement in the concrete matrix is just one of several ways of meeting climate neutrality for this common building ingredient. Innovation through new material combinations, digitalization, the radical reduction of waste, and the extension of the useful life of products and buildings are the driving forces in the transition to becoming a climate-positive material. The model for revolutionizing concrete is the opus caementicium, the cast masonry used by the Romans. The Romans added pozzolana as a binder, which gave the material a durability that often exceeds that of modern concrete. This durability remains on display today, illustrated by such famous examples as the Pantheon in Rome, built at the beginning of the 2nd century. Natural pozzolana has significantly lower CO₂ emissions during production. GRC elements with reduced cement content have 50 percent of the cement in the concrete matrix replaced by alternative materials, like pozzolana, resulting in a CO₂ reduction of 30 percent.

Photo © Ed White; courtesy of CRL

Architects not only have to strive to meet current energy codes but also look ahead to anticipate where codes are going. Planning for higher performance now, by embracing triple glazing and sustainable products, means meeting future targets today.

Incorporating glass offers another avenue toward sustainability. According to the Department of Energy, daylighting is a key building strategy that can save money for businesses. Through strategic placement of windows, skylights, and other fenestration, daylighting maximizes the benefits of natural lighting and temperature regulation.7 Daylight reduces dependency on artificial lighting to improve energy efficiency. Transparent glass walls can decrease reliance on interior lighting during daytime hours, reducing electrical consumption. The consequent reduction of reliance on electrical sources for producing interior light lowers energy costs and decreases a building’s carbon footprint. Depending on the lighting control system used, how well the space is daylit during occupied hours, and intended functions of the space, multiple studies in office buildings have recorded energy savings ranging from 20 percent to 60 percent when daylighting is used in place of electric lighting.8 Increasing the use of natural resources, such as daylight, by careful use of windows and glass within the built environment, reduces dependency on fossil fuels as well as combustion of greenhouse gases. Wise use of glass reduces the need for artificial lighting, lessens electricity costs, and creates a more sustainable building. Studies also show that with proper daylighting, productivity at the office goes up and absenteeism goes down.

Several factors contribute to creating the right daylighting: the type of window, window placement, and interior design all control how sunlight comes into a building. One of the most important decisions hinges on the right facade solution for the building.

Buildings account for approximately 40 percent of total energy usage in the United States. Building energy codes are thus becoming increasingly stringent, particularly when it involves the building envelope, as that is where most heat enters during hot months and escapes during cold months. Facades are a fundamental aspect not only of establishing a visual identity, but also of increasing the energy efficiency of a building. It’s critical that architects select the envelope systems—curtain wall, storefront, and entrance systems—that best meet their aesthetic intent, while providing superior thermal performance.

Today’s highly energy-efficient windows and glass entrance systems can reduce the need for artificial lighting during daylight hours without causing heating or cooling problems. Not only does daylighting offset energy usage, but it also aids occupant health. Relying on natural sunlight balances circadian rhythms and promotes better health and activity levels for those within the home. With documented research dating back to 1986, daylighting also has consistently been associated with improved mood, enhanced morale, less fatigue, and reduced eyestrain.9 Bright lighting enables enhanced focus and alertness, and well-daylit spaces are generally perceived by occupants to be “better” than dim, gloomy ones.10 Using glass allows people to enjoy distant, diverse, and dynamic views from the interior and establishes a link to the surrounding environment, which fosters connection.

END NOTES

1“The Clean Air Act Title IV – Noise Pollution.” United States Environmental Protection Agency. April 18, 2025. Accessed September 9, 2025.

2“Sheet-metal Facades by Mesker Companies – Preservation.” Illinois Historic Preservation Division. Illinois Department of Natural Resources. 2025. Accessed September 10, 2025.

3Ibid.

4“Sustainability Indicators 2024” report. World Steel Association. 2024. Accessed September 24, 2025.

5“American Steel’s Carbon Advantage.” American Iron and Steel Institute. Accessed September 25, 2025.

6“Energy 101: Daylighting.” U.S. Department of Energy. May 31, 2011. Accessed September 12, 2025.

7Galasiu, A. D.; Newsham, G. R.; Suvagau, C.; Sander, D. M. (2007). “Energy saving lighting control systems for open-plan offices: a field study” (PDF). Leukos, 4(1). pp. 7–29. Archived from the original (PDF) on 13 June 2010.

8Robbins, C. L. (1986) Daylighting Design and Analysis, New York: Van Nostrand Reinhold Company.

9Mardaljevic, J. (2012) Daylight, Indoor Illumination and Human Behavior in Encyclopedia of Sustainability Science and Technology Springer-Verlag New York Inc, New York. ISBN 978-0-387-89469-0, pp 2804-2846.

Amanda Voss, MPP, is an author, editor, and policy analyst. Writing for multiple publications, she has also served as the managing editor for Energy Design Update.